Our service system are used to clean, gasoline, diesel, ethanol blends, jet fuel, hydraulic oil, kerosene, and bio-diesel. Microbial contamination is removed from diesel fuel without emulsification.

Our service systems are designed to clean fuel with no loss of product.

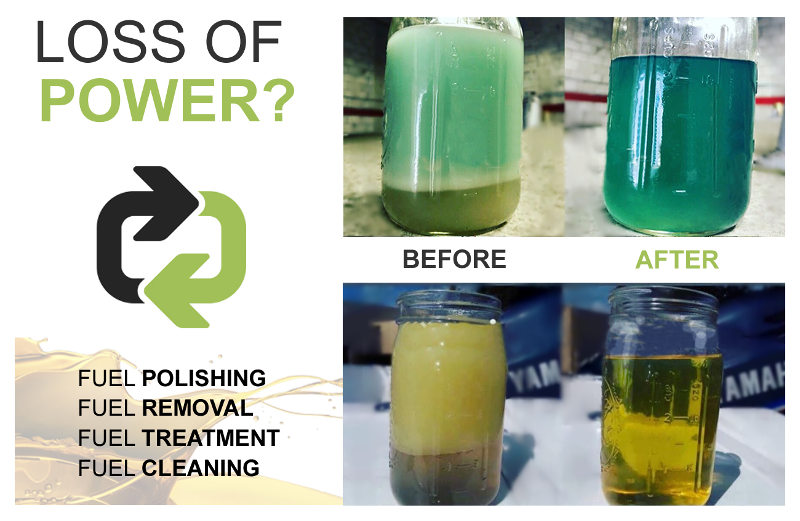

Fuel Polishing means removing contamination from fuel.

Water is your fuel’s worst enemy!

1. Water causes filter clogging bacteria, (algae), and fungi to grow inside your diesel fuel tank.

2. Water causes phase separation in ethanol blended gasoline.

3. Water damages fuel injection systems.

4. Water causes corrosion of steel storage tanks, STPs, and automotive components.

A high quality fuel polishing system will separate water from your fuel down to 50 parts per million. Anything less is not acceptable.

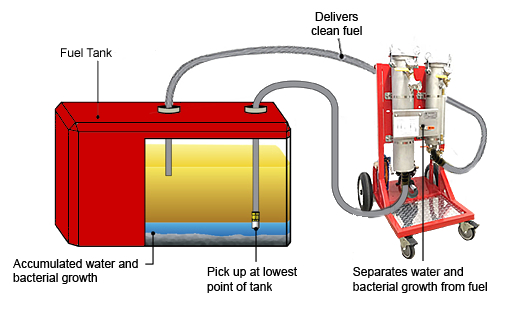

REMOVING WATER FROM A FUEL STORAGE TANK BOTTOM

It is not uncommon to find one or two inches of water in a fuel storage tank. However removing that water without mixing with the fuel causing emulsification, phase separation, or a substantial loss of fuel can be difficult without the proper equipment.

When high volume pumps or typical vacuum trucks are used to suck out the water; vortices are formed at the end of the suction tube causing the clean fuel above the water to be drawn into the whirlpool.

The result is more fuel than water being removed from the tank bottom.

FUEL POLISHING SYSTEMS

We use a systems that minimize the vortices, eliminate emulsification, and remove water from the fuel with state of the art water separators and no loss of fuel.

Two Inches (2) of Water in a 10,000 Gallon Fuel Tank is Only 36 Gallons.

REVIEWS

REVIEWS